Fully enclosed plug&play - truly smart

Our Compact Enclosure package

The turbocompressors are delivered ready mounted, cabled and tested within a plug&play acoustic enclosure of rigid construction. All required components for a fully functional compressor unit are fully enclosed within the package - for easy installation and commissioning.

Features

- Rigid powder painted steel construction

- Aluzinc panels with mineral wool dampending

- Lifting hooks and forklift access

- Seperate compartments for Softstarter, VFD or DOL

- For suction from blower room or inlet duct

- For piped exhaust ventilation from room

- Residual noise typically <75 dB(A)

- No peak noise during start/ stop

- With window and fringed doors for easy access

- Rated NEMA 3

The package includes the followig fully enclosed components

- Inlet silencer (labyrinth type, no foam material) and inlet grill

- Inlet G4-compact-pocket filter (ASHRAE 52.2)

- Flexible Joint and Discharge Cone

- Blow off valve and silencer integrated for noise reduction during start/stop

- Electrical drive motor

- Complete MCC System: Softstarter, VDF, DOL

- Local Control panel

Our Modular enclosure package

We also offer a traditional assembled-on-site accoustic enclosure. The structure is shipped in modules, which have to be finally assembled around the compressor unit on site. The inlet system, Local Control Panel as well as optional starter and motor control centers are stand-alone units outside of the enclosure.

Standard foot-mounted and D-flange electric motors

Standard B3/5 electrical motors of different brands; Softstarter/ VFD or DOL included in the package; Upgrade Instrumentation from known brands. An assurance of lifelong, commercially-available parts.

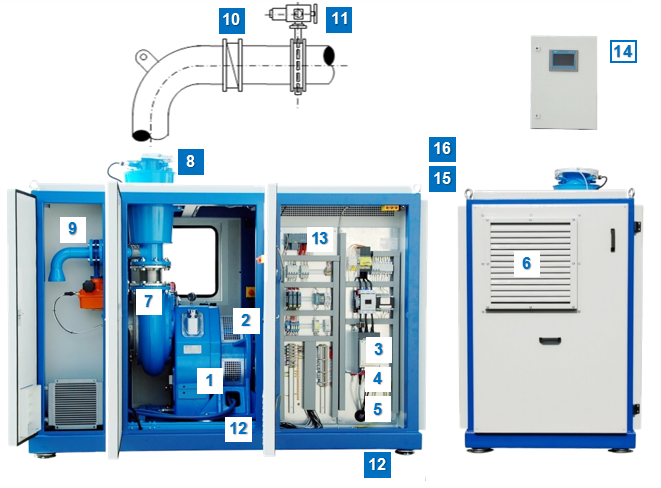

The package components

-

1.Turbocompressor

2.Electric drive motor

3.Variable Frequency Drive (VFD)

4.Direct Starter (DOL)

5.Softstarter (MCC)

6.Inlet silencer/filter

7.Flexible Compensator

8.Discharge diffuser

9.Blow-off valve/ silencer

10.Checkvalve

11.Isolation valve (electrical)

12.Vibration isolation mounts

13.Local Control panel

14.Master Control Panel

15.Compact enclosure

16.Modular enclosure

2016 © Next Turbo Americas - All Rights Reserved. Disclaimer | Legal Notice | Data Protection